While it’s evident that rising quality levels are accompanied by decreasing quality costs, it’s easy to forget what’s driving those improvements. To understand what they are—and what exactly they prevent—we need to turn to quality guru Armand Feigenbaum’s idea of the “hidden factory”. When a company takes steps to prevent problems before they happen, it demonstrates a commitment to quality and customer satisfaction. Customers appreciate knowing that their interests are the top priority for a business and that the company is doing everything possible to ensure their experience is positive.

Lack of Integration- Prevention Costs

The principles of Kaizen drive proactive problem prevention and enhancements to the quality management system, fostering creativity and collaboration with suppliers to meet new targets. On the other hand, excessive prevention costs can create a sense of micromanagement and distrust among employees. If prevention measures are overly strict or rigid, employees may feel they are not trusted to make decisions or take responsibility for their work. This can lead to feelings of frustration and disengagement, which can ultimately harm productivity and quality. Technology has revolutionized supply chain management by providing real-time visibility into inventory levels, supplier performance, and product delivery. By optimizing supply chain operations, companies can minimize the risk of delays, defects, and other issues impacting the quality of their products or services.

How Can Companies Measure the Effectiveness of Their Prevention Costs?

This includes leadership commitment, employee empowerment, and recognition programs. A quality management system like ISO 9001 provides a framework to implement quality best practices across the organization. Firms can also use industry benchmarks to evaluate how their quality costs stack up against competitors.

- This includes the broad array of activities which collectively create the overall quality plan and the numerous specialized plans.

- Building a brand like that is the outcome of its constant investment in the cost of quality, including the prevention cost.

- For example, if quality control measures require extensive paperwork and approvals, employees may spend more time on administrative tasks than on their primary responsibilities.

- The quality control department is primarily responsible and accountable for implementing the prevention cost, along with other cost of quality (COQ) measures.

The Company

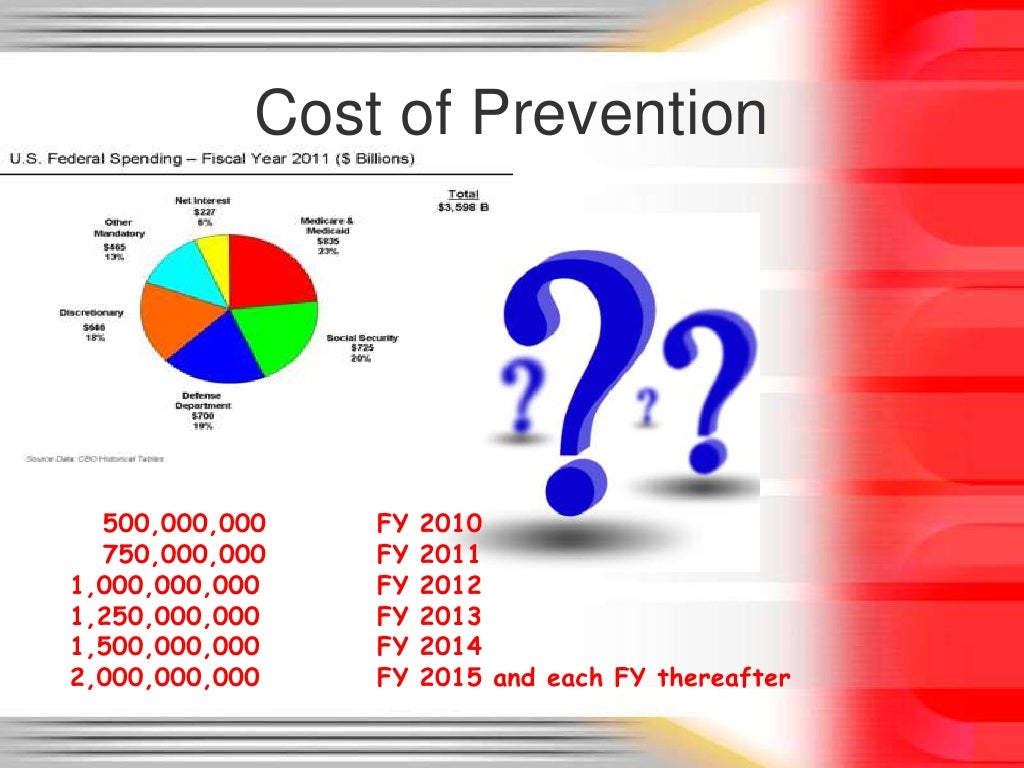

Some prevention costs, such as employee training or protocol development, may not be expensive. However, other prevention costs, such as equipment maintenance or inspection, can be more costly. Smaller businesses or startups may have limited financial resources, making investing in costly prevention measures challenging. The prevention cost refers to the costs incurred by companies to reduce errors in the production process.

There’s a lot to consider so it might be tempting to oversimplify or overcomplicate. While keeping things simple is good (particularly what are corporate budgeting exercises at the beginning—you can always add complexity to your model later), oversimplification can lead to missed costs and trends.

When implemented correctly, prevention costs can improve the quality of products and services, reduce waste, and increase customer satisfaction. Therefore, it is crucial to measure the impact of these costs to ensure that the investment is yielding the desired results. Prevention and appraisal costs are two types of quality control costs that businesses incur to ensure that their products and services meet specific standards. While prevention costs focus on preventing defects and errors from occurring in the first place, appraisal costs focus on detecting and correcting defects after they occur. Prevention costs encompass the resources allocated by a company to implement measures that reduce the likelihood of defects, errors, or failures in its products, services, or processes. Prevention costs play a critical role in ensuring product or service quality and enhancing overall business performance.

Appraisal costs are essential for catching defects and ensuring that products or services meet quality expectations before they reach customers. However, these costs often reflect a reactive approach to quality management, addressing issues that could have been prevented through better processes. In a business setup, the whole organization is responsible for ensuring quality production.

Employees should be encouraged to suggest improvements and identify potential risks. Employee involvement can be facilitated through team meetings, suggestion boxes, and feedback sessions. Effective implementation of prevention costs requires clear communication between employees and departments. However, some companies may struggle to establish effective communication channels, resulting in confusion and a lack of coordination between preventive measures. Implementing prevention costs requires accountability, where individuals are responsible for implementing preventive measures and ensuring their effectiveness. However, some companies may struggle to establish accountability for prevention costs, resulting in a lack of or ineffective implementation.

Customers will turn to competitors who can offer higher quality products or services, which can reduce sales and revenue for the business. When employees see that the company is not investing in prevention costs, it can lead to a lack of motivation and satisfaction in their work. This can result in decreased productivity and increased employee turnover, affecting a company’s long-term bottom line. Some industries may have stricter regulations or quality standards, requiring businesses to implement prevention costs earlier in their operations. Maintaining the equipment used by the employees throughout the day is crucial to delivering top-notch products and services.